High Wear Resistan Pumps Parts

Basic Info

Model No.: NP-AH(R)

Product Description

Model NO.: NP-AH(R)

Casting Form Material: Metal

Casting Form Usage Count: Permanent

Surface Roughness: Ra12.5

Machining Tolerance: +/-0.01mm

Certification: SGS, CE, ISO 9001:2008

Stock: Large

Delivety: Within 5days After Get The Payment

After-Sales Service: Perfect

Color: as Customer′s Request

Trademark: Naipu

Origin: Shijiazhuang City

Casting Method: Sand Casting

Casting Metal: Cast Iron

Surface Treatment: Sand Blast

Coating: Syrup or pulp waste

Standard: AISI

Material: High Chrome Alloy

Mqq: 1 Pic Slurry Pump Impeller

Manufacturer or Trader: Impeller Factory

Certificate: ISO 9001:2008, CE, SGS

OEM: Accept

Specification: CE

HS Code: 84137010

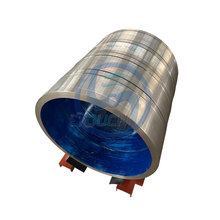

Impeller A05 for 14/12 Sand Gravel Pump

Parts Material : High Chrome alloy A05 , A49, A07 or as customer's requirement.

Weight :712kg

Nai Pu sand Gravel Pump Impeller interchangeable with G Series Sand Gravel Pump

6/4D-G Sand Gravel Pump impeller code: DG4137

8/6E-G Sand Gravel Pump impeller code: EG6137

10/8F-G Sand Gravel Pump impeller code: FG8137

12/10G-G Sand Gravel Pump impeller code: FG10137

14/12G-G Sand Gravel Pump impeller code: GG12137

Sand Pump Impeller Material

1. A05 is a wear resistant white iron that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of alloy A05 is provided by the presence of hard carbides within its micro-structure. Alloy A05 is particularly suited to applications where mild corrosion resistance, as well as erosion resistance is required.

2. A07 Marten-sic white iron with moderate erosion resistance.

3. A49 is suitable for low pH corrosion duties, where erosive wear is also a problem. The alloy is particularly suitable for Flue Gas Desulphu-rization(FGD) and other corrosive applications, where the pH is less than 4. The alloy can also be used in other mildly acidic environments. A49 has an erosion resistance similar to that of Ni-Hard 1.

OEM Service

Naipu is willing to any OEM order for pump and mining equipment, such as full set bare shaft pump and Pump parts. We have already designed and developed many special Slurry Pump successfully. Naipu can satisfy customers' any requirement based on our rich machinery manufacturing experience.

Contact

Contact person : kitty liu

What App: 86-13032609126

Sand Gravel Pump performance parameters

| Model | Flow (m3/h) | Head (m) | Speed (r/min) | Efficiency (%) | Motor (kw) | Drive type |

| 6/4 D-G | 187-36 | 7-51 | 1400-600 | 30-58 | 52-3 | CV.CR.DC |

| 8/6 E-G | 576-133 | 10-48 | 1400-800 | 60-54 | 88-11 | CV.CR.DC |

| 10/8 F-G | 930-216 | 11-44 | 940-500 | 65-34 | 147-22 | CR.DC |

| 12/10 G-G | 1512-360 | 11-58 | 850-400 | 70-50 | 305-24 | CR.DC |

| 14/12 G-G | 3168-522 | 9.5-66 | 700-300 | 68-60 | 643-29 | CR.DC |

| 16/14 TU-G | 3024-900 | 14-45 | 500-300 | 70-50 | 459-78 | CR.DC |

| 8/6 F-G | 648-126 | 15-77 | 1050-500 | 71-50 | 177-12 | CR.DC |

| 10/8 F-G | 1091-324 | 19.2-56.5 | 800-500 | 72-60 | 205-32.4 | CR.DC |

| 12/10 G-G | 2232-612 | 28-77 | 700-450 | 73-60 | 558-89 | CR.DC |

Contact us if you need more details on Impeller. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Impeller Gg12137、Impeller A05. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Wet End Parts > Other Wet End Parts

Premium Related Products

Other Products

Hot Products

8/6 Ee-Ah Horizontal Centrifugal Mining Slurry Pump2 Inch Mining Froth Pumps (2 QV-AF)Wq Series Submersible Centrifugal Sewage Water PumpFarming Irigation and Industry Deutz Diesel Water PumpShijiazhuang Pump Factory OEM Heavy Duty Copper Mining Processing 10X8 Slurry PumpL Series Wear Resisting Low Abrasive Slurry PumpZjw Series Strong Abrasion Resistant Feed Slurry PumpHigh Chrome Alloy Cast Iron Mining Solid Pump (HH)Spr Series Vertical Centrifugal Slurry Sump PumpZjq 300-30-55 Heavy Duty Submersible Dredging Sand PumpWsg Heavy Duty Sand Dredging Diesel PumpPaper Pulp and Flotation Using Vertical Froth Pumps (AF)Ce Certificated Single Stage Horizontal Centrifugal Dredging Slurry Pump14/12ff-Lr Large Centrifugal Horizontal Ash Slurry PumpSuction Dredge Sand Pump (150ZJS)12/10 St-Ah Heavy Duty Horizontal Mining Slurry Pump