14/12ff-Lr Large Centrifugal Horizontal Ash Slurry Pump

Basic Info

Model No.: 14/12 FF-LR

Product Description

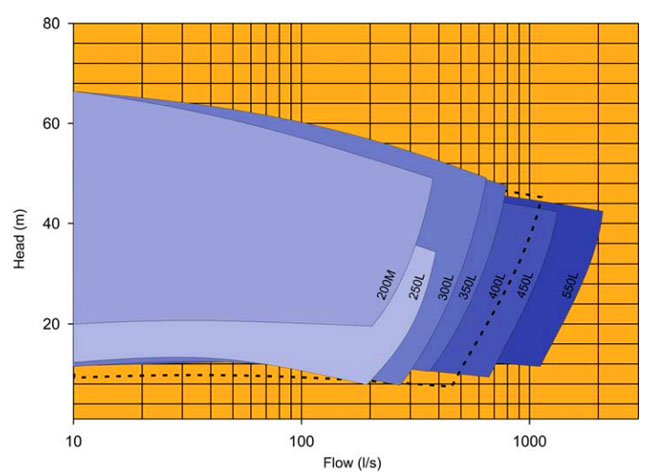

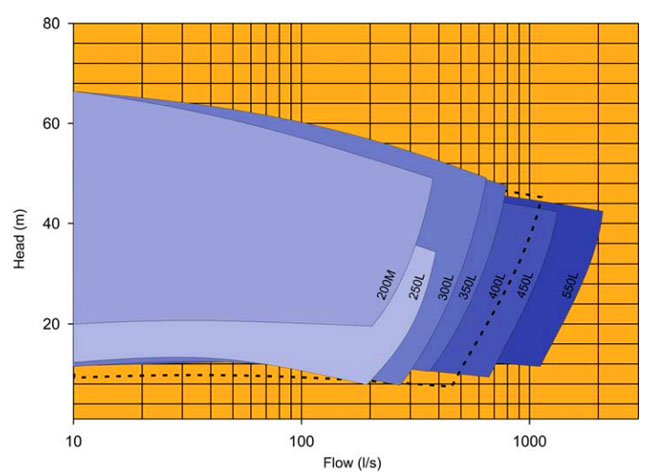

Model NO.: 14/12 FF-LR Max.Capacity: 700 L/S Impeller Number: Single-Stage Pump Influent Type of Impeller: Single Suction Pump Pump Casing Combined: Single Stage Horizontal Impeller: Closed OEM: Accepted Discharge Size: 1-18 Inch Material: R55, R26, R24... Specification: ZJR HS Code: 8413709990 Max.Head: 13-44 M Driving Type: Motor Working Pressure: Middle Pressure Pump Position of Pump Shaft: Horizontal Pump Mounting Height: Since Irrigation Centrifugal Pumps Usage: Pump Certificate: CE, ISO9001, SGS Drive Style: Dcz, Zvz, Crz Trademark: OEM Origin: China ZJR Slurry Pump Introduction:

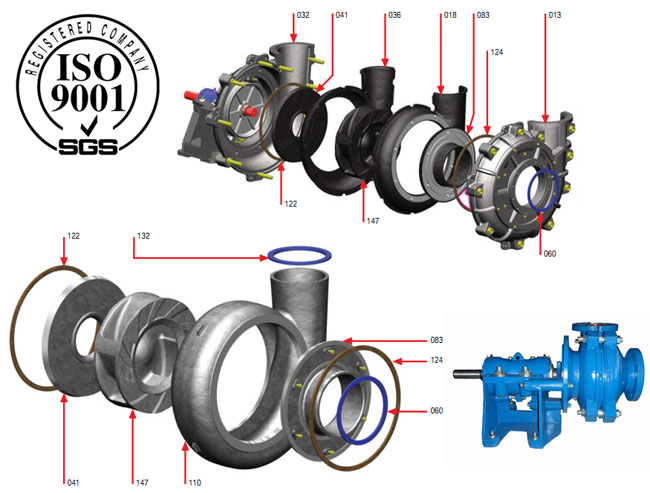

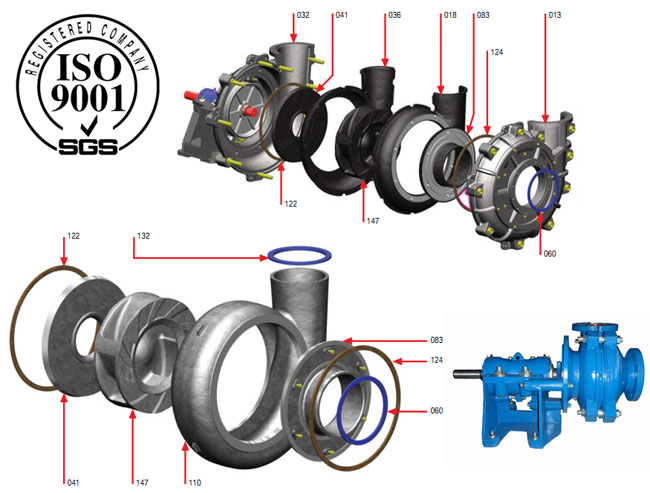

Our Slurry Pumps are suitable for pumping slurry with hard particles and in high density in industrial sectors as of metallurgy, mining, coal, power generation and building material. These pumps can also be applied multi-staged in series. They are classified into three types: M. AH. HH.

The M. AH. HH type slurry pumps are those of cantilever, horizontal and centrifugal ones, whose shafts can be sealed by packing seals or by centrifugal type seals. The positions of the pump outlet can be positioned at an interval of 45° According to different requirements, so eight different angles can be applied by rotation in installation.

The M. AH type slurry pumps have pump bodies (volute liners, front and back liners) that consist of replaceable wear-resistant metal liners or wear-resistant rubber liners, and impellers can also apply wear-resistant metal material or wear-resistant rubber material. The HH type slurry pumps only apply wear-resistant metal material as their pump bodies and impellers.

Application:

The Type Of ZJR-NP-AHR Pumps Are Using For Handing Strong Abrasive, High Density Slurries And Low Density, High Head Slurries In The Metallurgical, Mining, Coal, Power, Building Material And Other Industrial Departments etc.

For Example: Coal Washer Processing, Handling With The Fine Ore And Tailings In Metal Mine, Handing Combined Bottom And Fly Ash In A Thermal Power Station.

Contact us if you need more details on Rubber Lined Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Pumps、Rubber Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Rubber Lined Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Pumps、Rubber Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our Slurry Pumps are suitable for pumping slurry with hard particles and in high density in industrial sectors as of metallurgy, mining, coal, power generation and building material. These pumps can also be applied multi-staged in series. They are classified into three types: M. AH. HH.

The M. AH. HH type slurry pumps are those of cantilever, horizontal and centrifugal ones, whose shafts can be sealed by packing seals or by centrifugal type seals. The positions of the pump outlet can be positioned at an interval of 45° According to different requirements, so eight different angles can be applied by rotation in installation.

The M. AH type slurry pumps have pump bodies (volute liners, front and back liners) that consist of replaceable wear-resistant metal liners or wear-resistant rubber liners, and impellers can also apply wear-resistant metal material or wear-resistant rubber material. The HH type slurry pumps only apply wear-resistant metal material as their pump bodies and impellers.

Application:

The Type Of ZJR-NP-AHR Pumps Are Using For Handing Strong Abrasive, High Density Slurries And Low Density, High Head Slurries In The Metallurgical, Mining, Coal, Power, Building Material And Other Industrial Departments etc.

For Example: Coal Washer Processing, Handling With The Fine Ore And Tailings In Metal Mine, Handing Combined Bottom And Fly Ash In A Thermal Power Station.

| Type | Clear Water Performance | Clear Water Performance | Impeller | |||||

| Capacity/Q m³/hr | Head/m | Speed/rpm | Max Efficiency/% | NPSH/m | Nos of Vane | Diameter/mm | ||

| 20A-L | 7.5 | 2.34-10.8 | 6-37 | 1400-3000 | 30 | 3.5-8 | 4 | 152.4 |

| 50B-L | 15 | 16.2--76 | 9-44 | 1400-2800 | 55 | 3.5-8 | 5 | 190 |

| 75C-L | 30 | 18-151 | 4-45 | 900-2400 | 57 | 3-6 | 4 | 229 |

| 100D-L | 60 | 50-252 | 7-46 | 800-1800 | 60 | 2-3.5 | 4 | 305 |

| 150E-L | 120 | 115-486 | 12-51.5 | 800-1500 | 65 | 2-6 | 4 | 381 |

| 200E-L | 120 | 234-910 | 9.5--40 | 600-1100 | 64 | 3-6 | 4 | 457 |

| 250F-L | 120 | 396-1425 | 8-30 | 500-800 | 77 | 2-10 | 5 | 550 |

| 300S-L | 560 | 468-2538 | 8-60 | 400-950 | 79 | 2-10 | 5 | 653 |

| 350S-L | 560 | 650-2800 | 10-59 | 400-840 | 81 | 3-10 | 5 | 736 |

| 400ST-L | 560 | 720-3312 | 7-51 | 300-700 | 80 | 2-10 | 5 | 825 |

| 450ST-L | 560 | 1008-4356 | 9-48 | 300-600 | 80 | 2-9 | 5 | 933 |

| 550TU-L | 1200 | 1980-7920 | 10-50 | 250-475 | 86 | 4-10 | 5 | 1213 |

Contact us if you need more details on Rubber Lined Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Pumps、Rubber Part. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Rubber Lined Slurry Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Mining Pumps、Rubber Part. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Horizontal Slurry Pumps > Rubber Liner Pump

Premium Related Products

Other Products

Hot Products

8/6 Ee-Ah Horizontal Centrifugal Mining Slurry Pump2 Inch Mining Froth Pumps (2 QV-AF)Wq Series Submersible Centrifugal Sewage Water PumpFarming Irigation and Industry Deutz Diesel Water PumpShijiazhuang Pump Factory OEM Heavy Duty Copper Mining Processing 10X8 Slurry PumpL Series Wear Resisting Low Abrasive Slurry PumpZjw Series Strong Abrasion Resistant Feed Slurry PumpHigh Chrome Alloy Cast Iron Mining Solid Pump (HH)Spr Series Vertical Centrifugal Slurry Sump PumpZjq 300-30-55 Heavy Duty Submersible Dredging Sand PumpWsg Heavy Duty Sand Dredging Diesel PumpPaper Pulp and Flotation Using Vertical Froth Pumps (AF)Ce Certificated Single Stage Horizontal Centrifugal Dredging Slurry Pump14/12ff-Lr Large Centrifugal Horizontal Ash Slurry PumpSuction Dredge Sand Pump (150ZJS)12/10 St-Ah Heavy Duty Horizontal Mining Slurry Pump