Shijiazhuang Pump Factory OEM Heavy Duty Copper Mining Processing 10X8 Slurry Pump

Basic Info

Model No.: NP-AH(R)-L(R)-M-HH

Product Description

Type |

|

| ||||

|

|

|

| |||

1.2X1B-NP-AHR |

|

|

|

|

| |

2 X1 .5B | 15 | 25.2-54 | 5.5-41 | 1000-2600 | 50 | |

3 X 2C | 30 | 36-75.6 | 13-39 | 1300-2100 | 55 | |

4X3C | 30 | 79.2-180 | 5-34.5 | 800-1800 | 59 | |

6X4D | 60 | 144-324 | 12-45 | 800-1350 | 65 | |

8X6E | 300 | 324-720 | 7-49 | 400-1000 | 65 | |

10X8F | 560 | 540-1188 | 12-50 | 400-750 | 75 | |

12X10ST | 560 | 720-1620 | 7-45 | 300-650 | 80 | |

14X12ST | 560 | 1050-2520 | 13-44 | 300-500 | 79 | |

16X14TU | 1200 | 1200-3000 | 11-42 | 250-450 | 82 | |

20 X18TU | 1200 | 1800-4000 | 12-44 | 200-350 | 82 | |

Certificates

Certificates  Related Products

Related Products

Production Process

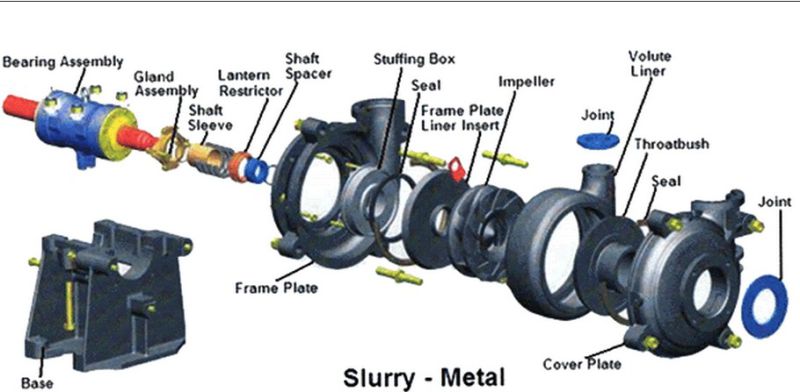

Production Process  Possible faults and removal Type AH(R) series pump has a compact construction. If it is correctly installed and operated, the pump will have a long life.

Possible faults and removal Type AH(R) series pump has a compact construction. If it is correctly installed and operated, the pump will have a long life. Faults | Reason | Removal |

Pump fails to discharge | Air leaking into suction or gland Incorrect direction of pump rota- tion | Sealed leakage. Check direction of rotation and replacing a new impeller. Removal lockage. |

Shaft Power consumption is excessive | Gland excessively tightened against packing rings. Rotating component is rubbing on a stationary part. | Loosen gland bolts. Removal the rubbed part. |

Bearing is over hearing | Lubricants too much or less. | Lubricating as requirements. |

Bearing has short life. | Misalignment or unparallel of drive Foreign object entered into the bearing or insufficient lubrication. | Adjusting drive and pump shaft. |

Excessive leakage from stuffing box | Packing rings excessive worn. Shaft sleeve worn. Dirty sealing water. | Replace new packing rings. Replace shaft sleeve. Change clean sealing water. |

Pump vibrates or is | Bearings worn. | Replaced by new bearings. |

Product Categories : Horizontal Slurry Pumps > Other Horizontal Slurry Pumps

Premium Related Products